The gasket is an additional layer of material affixed to the underside of the piece of main fabric and keeps its shape, the shape of the collar, cuffs, belt, cushions, strengthens the loop of the clasp. Padding used even in the simplest models to stabilize the neck, obrazek and bottom. Place, reinforced gasket, do not lose shape after long socks and repeated washing.

The functions of the pads:

the prevention part and cut parts from stretching; providing the necessary dimensional stability; fixing pre-given forms

Strips can be adhesive and nechaevym.

Working with nechaevym pads takes more time. Them, you must first pin it with pins or tack, and only the final Topstitch. Working with nechaevym strips is time consuming, but some thin, delicate fabrics do not withstand the high temperature of the iron you need when working with adhesive strips, so they should be strengthened only nechaevym. This refers to fabrics with decorative relief production, natural and artificial leather, suede, synthetic material with film coating.

The adhesive (or thermoplastic) strip currently most prevalent in the clothing industry. (fabric, knitwear, non-woven cloth) printed on its surface an adhesive coating. The purpose of imparting dimensional stability to the parts and parcels of clothing items, protection them from stretching.

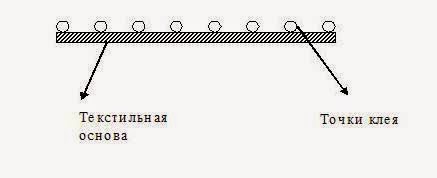

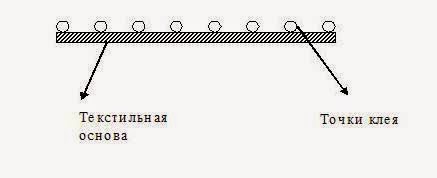

The schema of the adhesive strips can be represented in the form of a drawing:

There are the following types of adhesive pads:

Gasket materials based on woven – clothing inserts. They are intended for the manufacture of coats, jackets, uniforms, etc. Coated with polyamide adhesive, resistant to chemical cleaning, tkie gaskets are produced in two types, differing by size and location of the glue points: - with large, rarely spaced adhesive points for bonding with heavy woolen fabrics (tweed, gabardine) with the texture or podvorovoy. with small, tightly spaced glue spots, thin fabrics with a smooth surface. From woven strips distinguish the direction of the grain lines, so it should be taken into account when cutting. Shirt packing materials. Stiffen the collars and cuffs of shirts and blouses, covered with plastic adhesive, recommended for shirts and blouses from Khlopkov, lunohodchik and viscose fabrics, durable to washing in water with a temperature up to 90 C. Gasket materials on non-woven basis - interfacing. Non-woven gasket is a compressed mixture of fibers, making not to crumble the slices. Such a strip can be cut in any direction. Used in the manufacture of a wide range of clothing - surface mass ranges from 30-120 g/m2, coated with adhesives of different kind (viscoplastic polyester, polyamide) and different technology application (powder, paste, double point); it provides the ability to match the strips for each fabric type. Gasket materials on a knitted base. Used for the manufacture of a wide range of "mild" outerwear — jackets, coats, vests, etc. to provide the elasticity of the base layer. Have, as a rule, spot a polyamide adhesive coating. Are more soft and flexible than fliseline and doubleline the same surface density

Thus, all of the adhesive strips can be processeditorevent sleduem follows: