Despite the fact that foreign manufacturers of adhesive materials, usually accompany their products sets the technical characteristics of the adhesive pads of various articles and practical recommendations for their application and conduct a scientific-practical seminars, there is still no clear evidence-based methodology for the selection of cushioning materials. When choosing a specific adhesive strip , you should consider the effect you want to duplicate, and the following characteristics of the material of the top:

- The surface density (the sum of the surface densities of the lining and the strip should not exceed the surface density of the material of the top, so as not to burden the product);

- Of the product, operating conditions and plot duplication (for Example, for the manufacture of shirts, overlapping collars, cuffs, experiencing significant abrasive impact and are often subjected to washing, use strip with a continuous coating of plastic adhesive, resistant to washing; for the manufacture of men's coats, local duplication of parts of the front of the thick fabrics used strip with polyamide adhesive, resistant to chemical cleaning with an irregular dot coating, usually on a fabric basis for providing greater dimensional stability. You should not use spacers with large glue dots to duplicate a thin tissue to prevent migration of adhesive to the front side of the basic material);

- The color of the upper material (to prevent migration of the fibers of the strip through the layer of the main material it is not necessary to use white cushioning materials in dark basic tissues and Vice versa).

- Required processing temperatures (melting temperature of the adhesive cushioning material must be below the temperature of damaging the fibers or dye of the basic material; there are special pads for duplication of tissue with low resistance in which is applied the adhesive with a melting point of less than 90 degrees or the system of dots "Dubspot");

- A view of the reverse surface of the basic material (there are special pads for duplication of fabrics with a pile, inside-out surface, which hampered the formation of adhesive joints);

- The main material shrinkage (shrinkage of the strip should not exceed the value of the shrinkage of the core material).

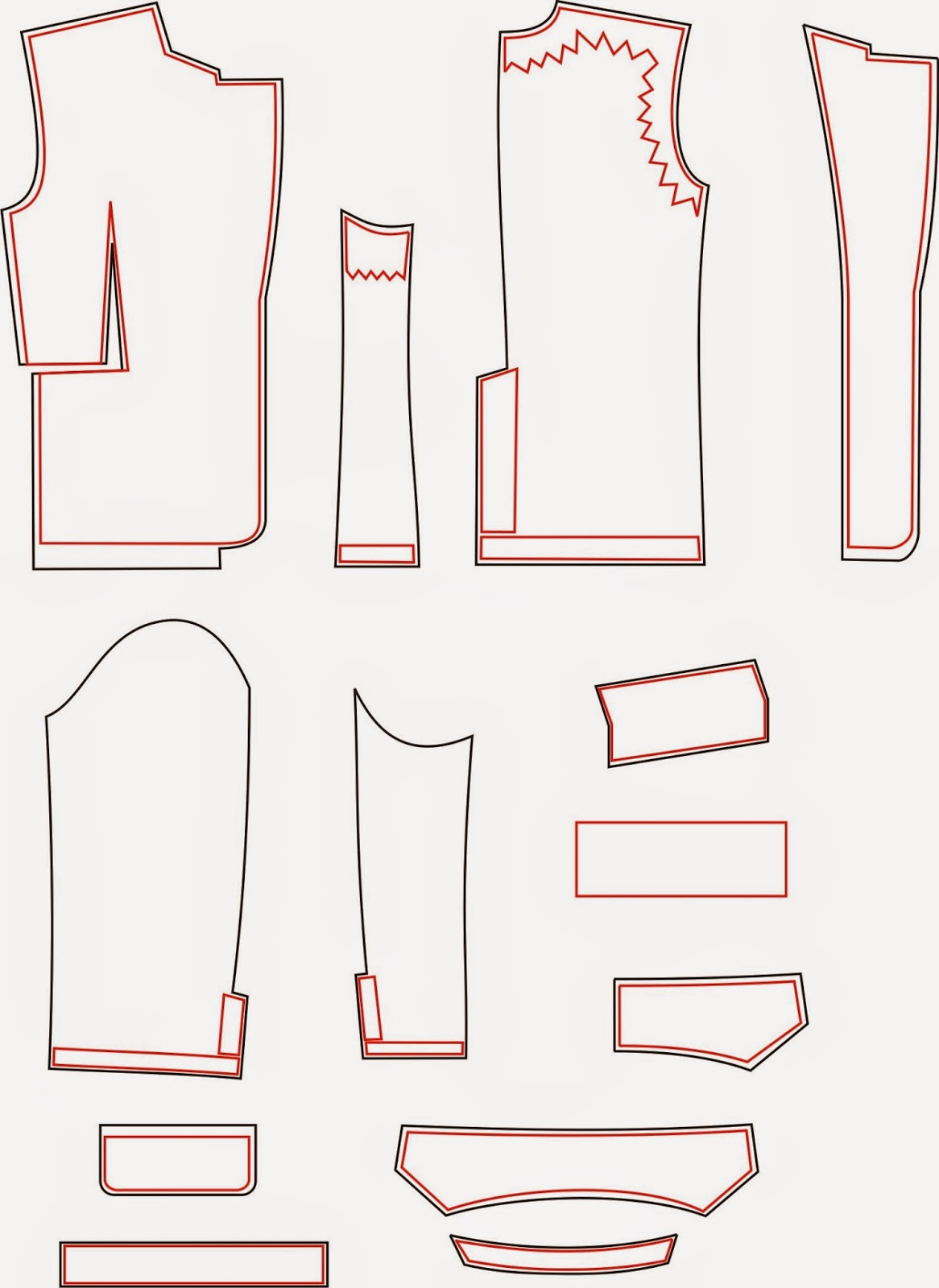

Examples of use of pads in the product shown in figure (the location of the pads marked in red: