When performing the WTO uses the following equipment:

- press , used for various time-consuming operations, the wet-heat treatment. The use of presses can significantly increase the productivity of operations and increase the processing quality of the product. The operating parts of the steam press are two metal heating pillow - top and bottom. Depending on the purpose of the cushions is made in different sizes and shapes. Often, the shape pillow conforms to the shape of the workpiece, but there are a versatile pillow that you can use to treat different areas of the product. Modern presses are equipped with means of automation, which not only regulate the heating temperature of the upper cushion, but the exposure time of the product between the pillows, the pressure, the time of steaming.

Structurally, the press can be of Electromechanical, pneumatic and hydraulic actuator. Depending on pressing forces of the press are divided into:

- light;

- medium;

- heavy.

- irons and Ironing tables. They are used to perform various operations of the wet-heat treatment in the manufacturing process and the final finish of the product. Irons are divided into light, medium and heavy. Depending on the nature of the heating irons are divided into:

- steam – heating of the sole plate produces steam;

- electric – heating of the iron takes place at built into the sole heating element Heater

- paraelectricity allowing the superheating process steam with the built-in sole of the heating element of the Heater.

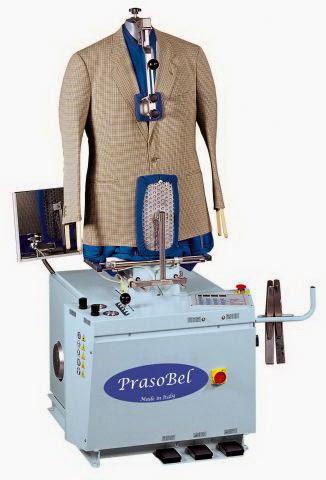

- steam-air dummies are used for final processing of various products. At processing on paromanekeny must to iron to press the edges of collars, lapels, collar and bottom.

- steamers, used for the removal of production garbage and Las, that is, the excess of lustre, arising from contact with surfaces of equipment for the WTO;

- dekotirovalis used to set the forced shrinkage of the textile material before cutting;

- progenerator, is used to generate steam.

The ability to control one or other of the WTO regime depends on the specific type of equipment, and establishing specific values for the regime — from the properties of the processed material or batch of materials and the ultimate goal of treatment.

Since clothing even within one type of product has a large number of differences in form, finishing elements, length, configuration of parts and assemblies, dimensional signs, is made of the different material properties within one product, there are areas of various curvature of the surface, requiring the WTO to ensure the possibility of using universal equipment (irons, in press) developed a large number of devices. These include:

- cushion (for presses), and stationary and portable pad (for irons) to handle different parts of the product on one workstation.

- the spray device for uniform distribution of tiny droplets of moisture on the surface of the material used for the equipment of the WTO is not equipped with a humidification system or steaming of the material;

- proteinlike fabric, cotton fabric nevorovannoe, stacked between the treated area and the working surface. Proteinlike you want to use for the WTO products from the materials forming the Lasy from contact with the working surface of the equipment

The list of accessories goes on, as they are not expensive, can be made in fact, the clothing manufacturer based on products, and greatly improve the processing quality.