The quality of finish and functional elements of the sewing goods are often used items such as valves, leaflets, PATA, shoulder straps, plastiki, belt, cuffs, and belt loops. The following is the information about handling of the valve.

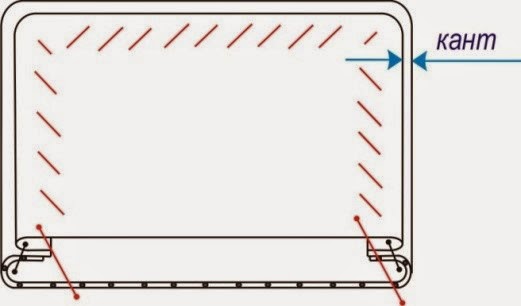

The valve sewing products are used as decorative element and for processing the entrance to the pocket. They may have a different shape. Valves are processed in the lateral and bottom sides, and attached to the product only on the upper side. In the products of suiting and overcoat fabrics for processing the valve need the following details: valve, lining valve and the valve gasket. Seam allowance seam grinding on bottom and side sections of the valve set 0.5-0.7 cm, primaqiune to front detail 1-1,5 see the Direction of the warp threads on the valve should match with the equity line of cloth on the front in imposing the upper edge of the valve along the line marking the pocket, in the lining of the valve - along parts in the valve gasket if it is cut in the shape of adhesive material on a fabric basis – in valve. The valve gasket is specifically made for 3-4 mm below the valve for all sections, so that it entered under the line of grinding parts. Lining cut out valve less valve 1.5-2 mm on the side and bottom cut so that, after grinding the valve was easy to rectify Kant. Products dress-blattneho range of valves can be one-piece with lined valve. The processing of such valves is reduced to the grinding of the side sections W.sh. 0.5-0.7 mm, trimming seam allowances, wyvernian on the front side and preatorian. The process valve can be present in the form of a table -- instructional-routing. № PP the Name of technologically indivisible operations of Technical conditions, Sketch, drawing, diagram 1 Duplicate valve lined valve From the wrong side, putting the gasket is symmetrical relative to the lower and side sections

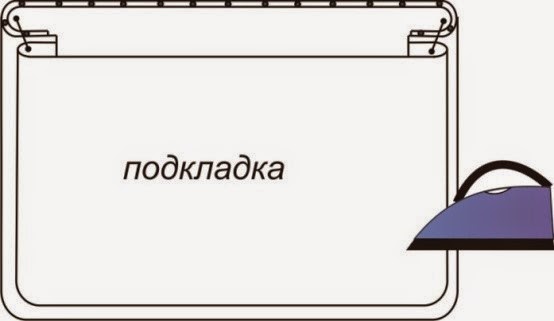

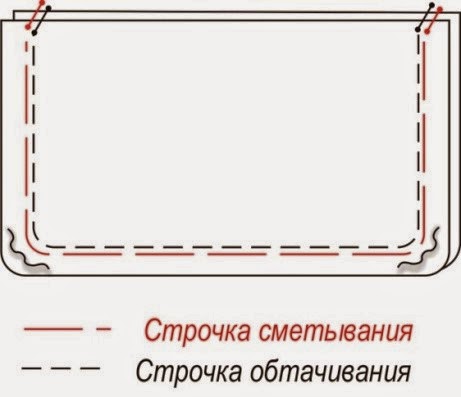

2 Sweep valve lined valve Folding parts, right sides inside, equalizing sections, smatyvay from the valve, sh.sh. 0.6 cm, Posiva valve on the curves

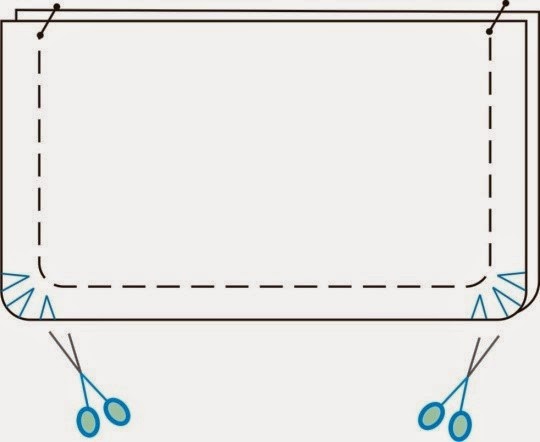

3 Oblachat valve lined valve From the lining of the valve, sh.sh. 0,5 -0,7 cm 4 Trim the seam allowances grinding valve lining valve rounded, not reaching line of 1.5 mm, while removing threads temporary destination

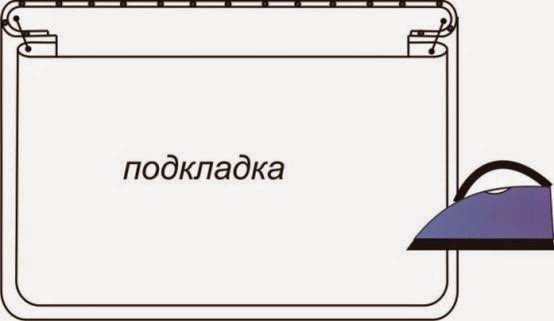

5 to Straighten the valve On the front side, straightening the corners 6 to Sweep the edge of the valve from the lining of the valve, slant or straight mymethodname stitches, straightening Kant from the valve 1 mm

7 Priotity valve from the side of the lining, moisture 8 Remove the thread to the temporary duty assignment

9 Priotity valve from the lining, moisturizing