When using a sewing machine (lockstitch duntocher) you should know some tricks or little secretsthat can greatly simplify the task and get a good end result - a smooth line, durable connection of the parts with minimum effort. Here are some of them:

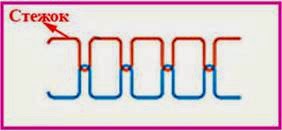

A properly made Shuttle stitch, and how to fix the line at the wrong puff stitch

Correct tightening of the twin lockstitch assumes that the knot is inside weave sew materials. Improper tightening of the knot goes on the bottom or the top surface of the sewn parts, may form a "beard". If the knots of the weave visible on the surface of the top layer material,this means that the lower thread Satanta enough, and the top is redundant.

If the knots of the weave formed below the situation is reversed, verista nitika too loose and bottom is tight. The solution is clear from the definition of reasons: ostavlyaetsya or is more tension on the upper thread (discs of the upper tension regulator thread)

or bottom thread (by twisting screw spring tension of the thread on bobbin case cap).

Important: if excessive tension on both strings have a knot weave within the material, but by the line of stitching may be tightness, especially in soft materials. When there is insufficient tension on both lines there is another defect - "toothy line" when stretched across the connection between the parts visible gap.

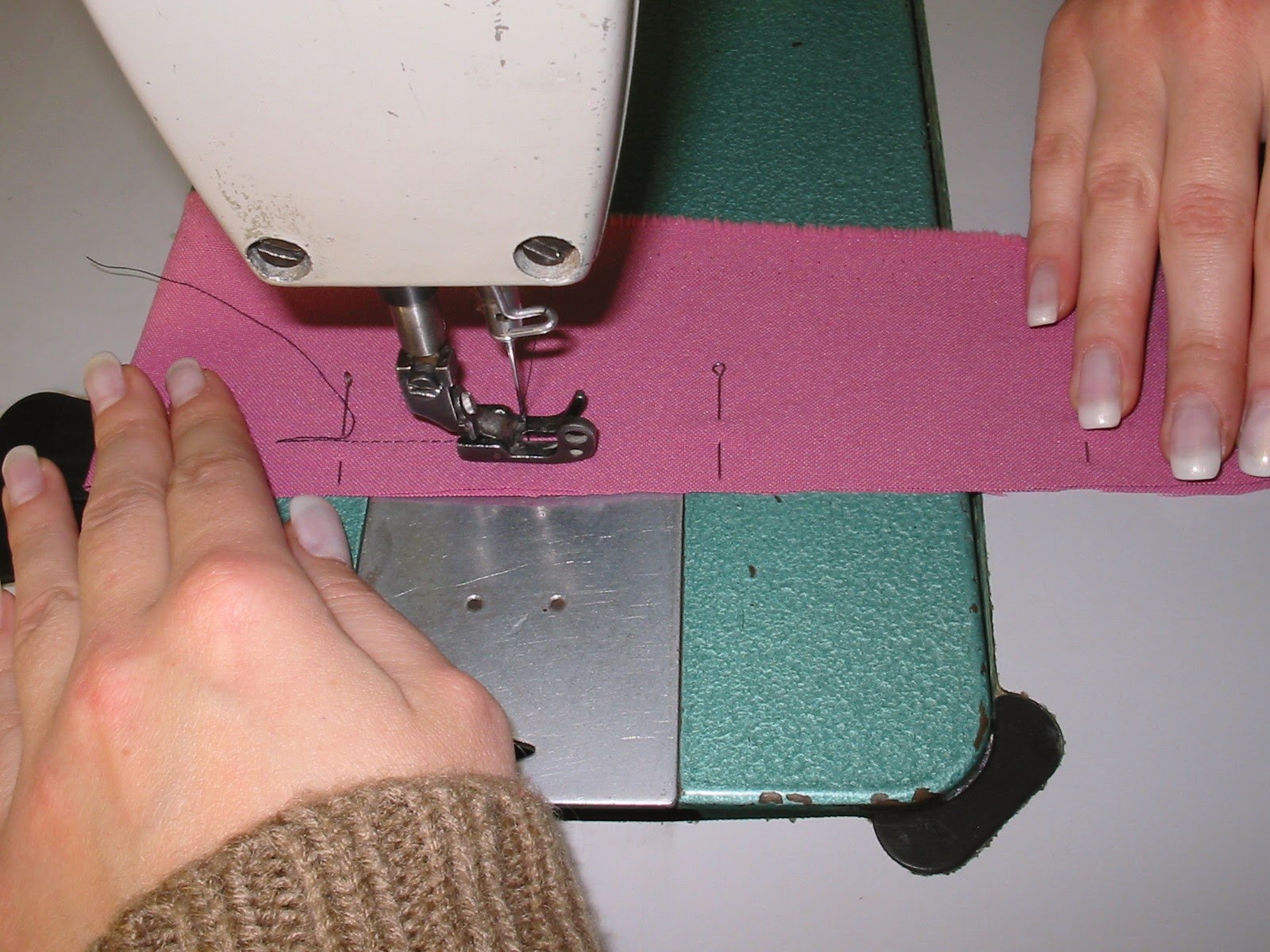

Bond pins when executing machine line

Instead of smachivaniya the time the paving machine stitch the parts can be fastened with pins. In this case, the pins are injected across the line for future connections so that they are easy to remove (for example, left hand). In some cases, the pin can not get out of the fabric before the presser foot the needle will slide right off it, performing a normal line.

The loose fitting bottom layer and Assembly of parts by lines

In most universal sewing machines when stitching long sections going to Board the bottom layer. The cause of the landing is solid contact of the lower layer of material with the tines moves the slats and braking the top layer of the sewn material presser foot. In some cases, when handling the valve or collar, with landing - this feature is used for normal distribution of planting machined parts.

In other cases, the fit of the lower layer is a defect. To reduce landing you can use the following methods:

- pre-smatyvay or chop off slices.

- slightly stretch seam under the presser foot of the machine;

- put the paper under the bottom layer of material;

- to apply the Teflon and roller feet in particularly difficult cases (leather, materials with a high synthetic content);

- to use the machine non-stop stitching (with the mechanisms for moving materials VI a lower toothed rack and moving the needle or sabatai the bottom rail with the top of the gear legs).

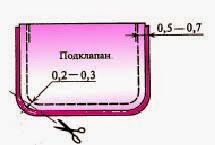

Build

The easiest machine to assemble without special devices is the following: increase the stitch length to 5 mm, loosen the upper thread and stitch a line of 7-8 mm from the cut edge, which is planned to build. Then you need to pull the slice to the required length.