Finishing seams - the last of the 3 identified groups of joints (according to classification). We will describe similar and connecting boundary: the name of the scheme, the process of manufacture with the specifications and example applications. Be patient - soon the end of...

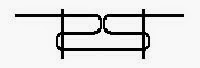

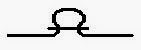

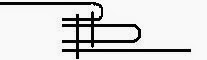

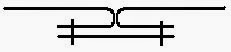

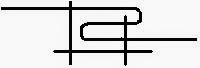

Simple finishing crease

Application field: finishing of solid parts, the pleats description of the process execution possible:

The crease outlines from the inside three lines: middle, side and perpendicular to them by the line bounding the end of the grinding pleat (if pleat is supposed to grind to a certain level) Detail bend the face inward on one's intended line and smatyvay a second longitudinal intended line or grind to transverse the intended line. Fold priorivet, thread smachivaniya removed.

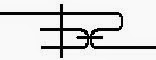

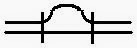

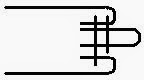

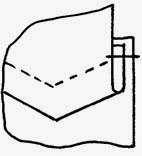

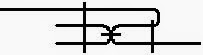

Complex finishing crease

Application field: finishing of solid parts, the curved folds of a description of the process execution possible:

On the front side outlines two lines: the location and depth of the folds. From the wrong side of the line of depth folds pritachivajut strip x/cotton fabric Strip giving way on one side, fold zametyvayut, bending, facing outward for the second line and priorivet. Lay the fixing line, nastraivat detail on the strip x/cotton fabric. Removed threads temporary destination. Simple connective pleat

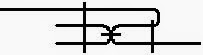

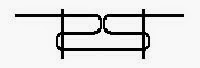

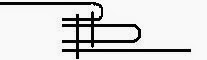

Scope: furnish prefabricated parts pleats description of the process execution possible:

Pleated scheduled on the same part from the inside two lines: line depth and perpendicular to the line delimiting the end of the grinding pleat (if pleat is supposed to grind to a certain level) Details fold right sides and grind off sh.sh. 10 mm. Details smatyvay through the depth of the folds or grind off to cross the line. Fold priorivet, thread smachivaniya removed.

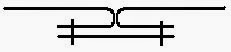

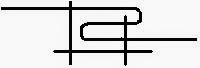

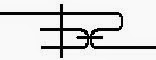

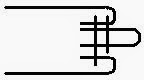

Complex connective pleat

Scope: furnish prefabricated parts pleats description of the process execution possible:

The edge of the top items iron inside out at a depth of pleats + 7 to 10 mm On the front side of the bottom part plan a line of orientation of the bend of the top part. The upper part is applied to the front side of the lower bend to the intended line (rarely with a combination of slices), and scribbled not the depth of the folds.

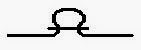

Finishing the relief vitaclay

Applications: surface finishing of shirts, dresses description of the process execution possible:

Outline the topography of a single line from the front side Detail of the bend on the planned line right side out and zastrugivajut sh.sh. 1-3 mm Detail unfold Finishing the relief vstrechnoy

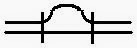

Scope: furnish products description of the process execution possible:

On the front side of the part outline two parallel lines at a distance of 5-10 mm from each other. When routing the lines from the inside enclose a strip of cotton or lining fabric forming a yoke for threading the cord. If you use bulk material for the substrate or set of slack when routing the second line is achieved three-dimensional effect of the seam.

Finishing vitaclay simple

Application field: finishing of products (imitation articulation) a description of the process execution possible:

Outline the topography of a single line on the reverse side of the part The bend detail on the intended lines face inward, put on a strip x/cotton fabric and scribbled sh.sh. 1 mm The upper part of the bent part and re-scribbled on a strip of cloth W.sh. 5-10 mm Finishing vitaclay complex

Application field: finishing of products (imitation articulation) a description of the process execution possible:

On the front side of the part outline relief. Lay the line along the line, enclosing on the reverse side under her striped, cotton fabric. Detail of the bend inside out out regarding connection lines and prokatyvajut at her place sh.sh. 1-2 mm The upper part of the bent part on the front side and scribbled it on a strip of cloth the width of the joint specified by the model.

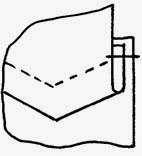

Finishing with piping connecting

Application field: finishing of joints details of edges description of the process execution possible:

Strip for Kant soutiiwest in half lengthwise right side out Striped pritachivajut to one part, stacking it on the front side of the part with a combination of cuts, sh.sh. 4-14 mm Details grind off sh.sh. 5-15 mm Allowances of seams in stitching details rautureau

Finishing with piping boundary

Application field: finishing the edges of the piping details description of the process execution possible:

Strip for Kant soutiiwest in half lengthwise right side out Striped pritachivajut to one part, stacking it on the front side of the part with a combination of cuts, sh.sh. 4-6 mm Details grind sh.ø 5-7 mm Detail turn relative to the connection lines 5. The edge of the part and straighten priorivet.