The order of the description of the edge seams will be the same as connecting: the name of the scheme or section, example applications, a description of the execution process and the possible technical conditions (TU). Forward..

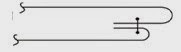

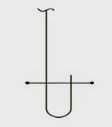

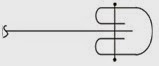

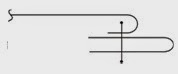

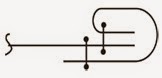

Regional oblasnoy in Kant

Area of application: processing of edges - the edge of the Board, collar, valve.

Description of the process execution possible:

Fold the details right sides inward, combine the slices and grind sh.sh. 5-7 mm Details turn on the line connection. One piece straighten Kant 0,5-3 mm and fixed by the WTO. Kant requires fixing and finishing stitching, spuskay or method in a "pure land".

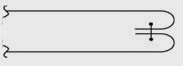

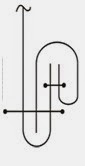

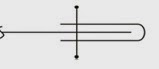

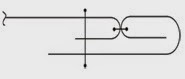

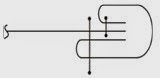

Regional oblasnoy in split

Area of application: processing of edges - the edge of the Board, collar, two-way products.

Description of the process execution possible:

Fold the details right sides inward, combine the slices and grind sh.sh. 5-7 mm Details turn on the line connection. The stitch straighten and record of the WTO. Seam requires fixing and finishing stitching, spuskay, or method in a "pure land".

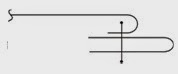

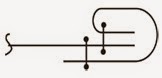

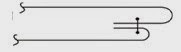

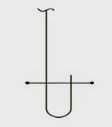

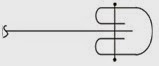

Regional oblasnoy frame simple

Scope: processing of Welt pockets in the products of thin and medium thickness fabrics, oblachnykh loops, slots, secret zipper.

Description of the process execution possible:

Strip of fabric for piping iron, bending along the underside of the inside in half. On the parts front side plan a line of orientation bend piping. The stack facing the fold in the planned lines and pritachivajut sh.sh. 4-10 mm Obtachku deployed relative to the line of primaqiune, allowances folded in the side of the part and fix through the WTO

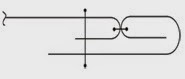

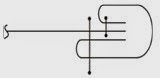

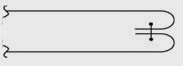

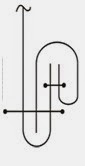

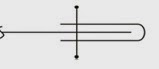

Regional oblasnoy in the frame of complex

Scope: processing of Welt pockets in the products of fat tissue, treatment Welt pockets with a curved line of the cut

Description of the process execution possible:

Part and fold the facing right sides inward, combine slices and pritachivajut obtachku sh.sh. 4-10 The seam allowances of the piping primaqiune rautureau The facing seam allowance trace the seam of her primaqiune and lay a line of sh.sh. 1 mm or the seam primaqiune piping

Regional bodybu open cut

Application field: processing of the bottom product and sleeves of dresses, skirts, trousers.

Description of the process execution possible:

Detail bends on the wrong side of 10-30 mm, zametyvayut or iron. Lay line (usually the front side) so that from the line before the cut was not less than 5 mm

Regional itagiba with a shut cut

Application field: processing of the bottom product and sleeves of dresses, skirts, pants, blouses, shirts.

Description of the process execution possible:

Detail bends on the wrong side of 10 mm, then another 10-30 mm, zametyvayut or iron. Lay line to sh.sh. from the stitching to the top of the ACC was 1-2 mm.

Regional itagiba with a stitched lining

Scope: processing of bottom of sleeves and products with a stitched lining

Description of the process execution possible:

Lining pritachivajut to the product sh.sh. 10 mm, folding front sides inward. Allowance for the processing of hem iron on size 30-40 mm, from the lining to form a fold 10 mm

Regional itagiba with an angled cut

Scope: processing of bottom men's coat, women's products without the lining of expensive fabrics or products quilted with insulation lining.

Description of the process execution possible:

A strip of cloth for edging added to the allowance for processing of the hem, right sides inside, combine slices, pritachivajut sh.sh.7-10 mm Edging round the lower section. Allowance for processing bottom bent 30-40 mm, zametyvayut or iron. To secure the seam allowance is laid stitching in the seam of protecive edging. Line 3 can be routed with the capture only of the allowance for processing of the bottom and of the free allowance border. The allowance can be fixed countersunk blind stitch stitching.

Regional listing, with an open cut

Application field: processing of the cut parts to prevent the fraying and to finish

Description of the process execution possible:

Striped edging applied on the front side details, combine slices and pritachivajut sh.sh. 3-10 mm Stripe round slices, forming edge with a width of 3-10 mm, and the free edge of the strip secured by stitching in the seam of primaqiune strips.

Regional listing, with a shut cut

Application field: processing of the cut parts to prevent the fraying and to finish

Description of the process execution possible:

Striped edging applied on the front side details, combine slices and pritachivajut sh.sh. 5-10 mm Stripe round slices, forming edge with a width of 5-10 mm. the Free end of the strip to buckle inside 4 to 9 mm and fixed line W.sh. 1 mm overlapping seam primaqiune strips to the part. When you use this binder handle suture is a single line (see diagram below)

Boundary edging braid

Application field: processing of the cut parts to prevent the fraying and to finish

Description of the process execution possible: Tape round the cut parts and fix it with a line sh.sh. 1 mm from the edge of the braid. The width of the border 3-10 mm.