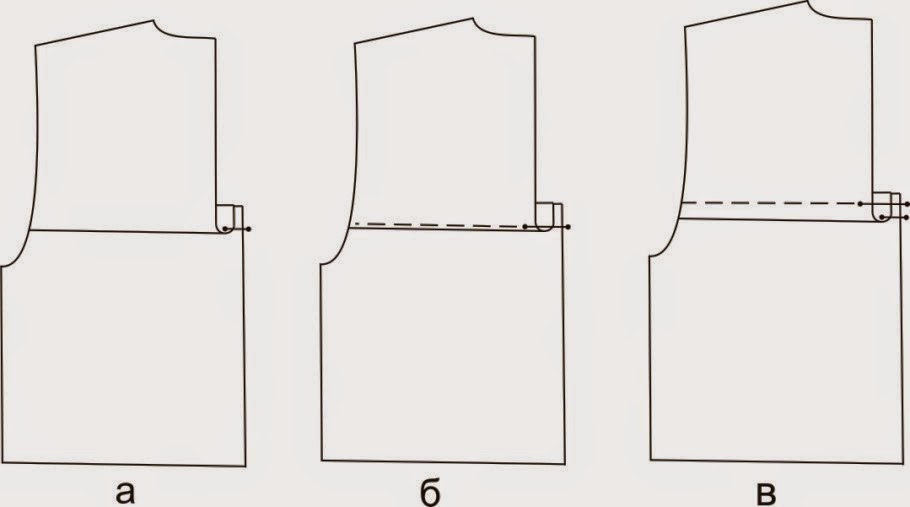

Coquette (cutting parts with a horizontal cutting line) used in the models of clothes are stitched and unfastened. A stitched yoke prisoedinyaetsya in different ways depending on the configuration of the line attaching, the presence or absence of a finishing line at the connection. A stitched yoke with a direct line of accession can preticipate sh.sh. 1 cm septugenarian seam allowances towards yoke (a), nastraivatsa sh.sh. 0.1 cm, with the prior sauturaga lower edge of the yoke inside out 1 cm (b), or to join the connecting sew-in sock seam with an open () or closed cut.

If when joining a stitched yoke in a straight line , you need to perform finishing withtracku at a distance of 2-4 cm, there are several treatment options

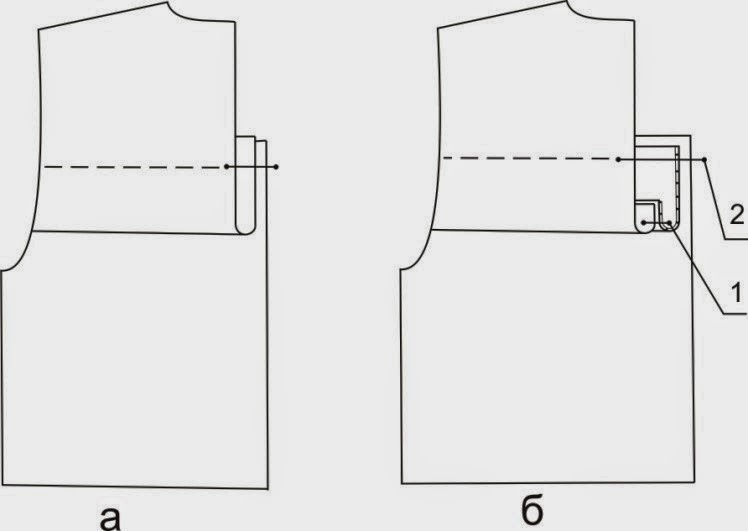

For example, to the lower cut yoke set allowance of 3-5 cm, which soutiiwest inside out and the yoke nastraivatsa in detail the necessary joint width (a). You can enter additional detail - the facing yoke, the width 3.5-5.5 cm, which is duplicated (b), and it turned the lower section of the yoke W.sh. 0.5 cm (p. 1), the seam grinding prietaisams with straightening Kant from the yoke, and the yoke nastraivatsa at the main part (p. 2) required width of the seam. If Flirty curly, processing scalloped edge and joining the yoke can be made using piping, repeating the configuration of the lower edge of the yoke, according to the scheme b.

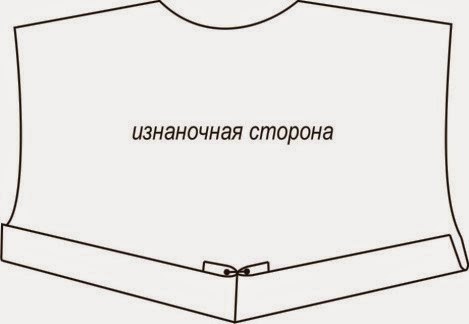

In some cases, you can use the allowances to lower the cutoff yoke: stitch allowances in the curved corner of the yoke W.sh. 0.7 cm seam grinding razorujaemsa, trimmed, and area viverravidae on the front side. Further, the yoke nastraivatsa for the core part:

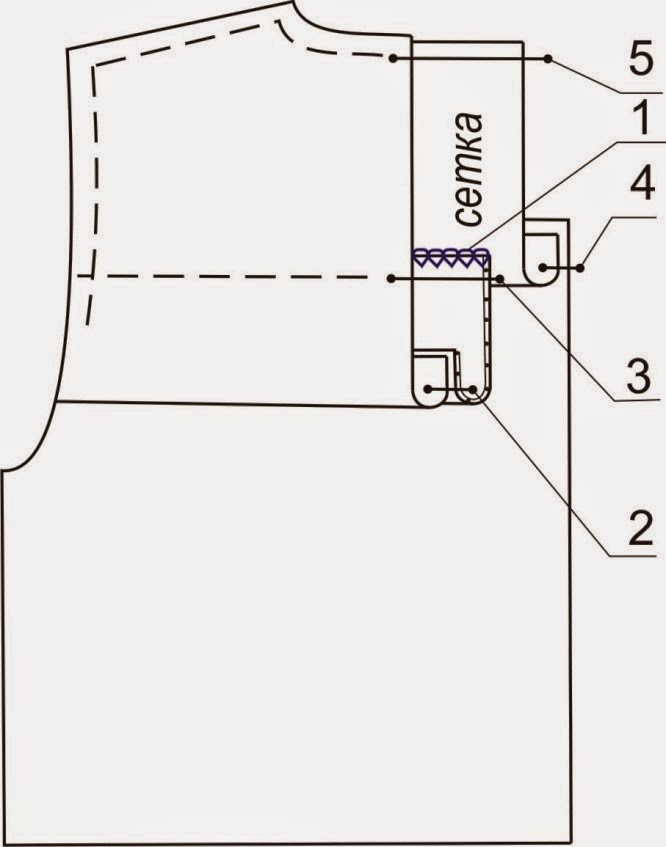

Storm flap design in the jackets, coats types of clothes, which gets the main material is breathable, and you must provide comfortable clothing for the conditions. Therefore, the backrest can be made of two parts, the upper part, not visible under the yoke, to carve out of mesh or another breathable material. Processing this node consists of processing the yoke and attach the yoke to the details: