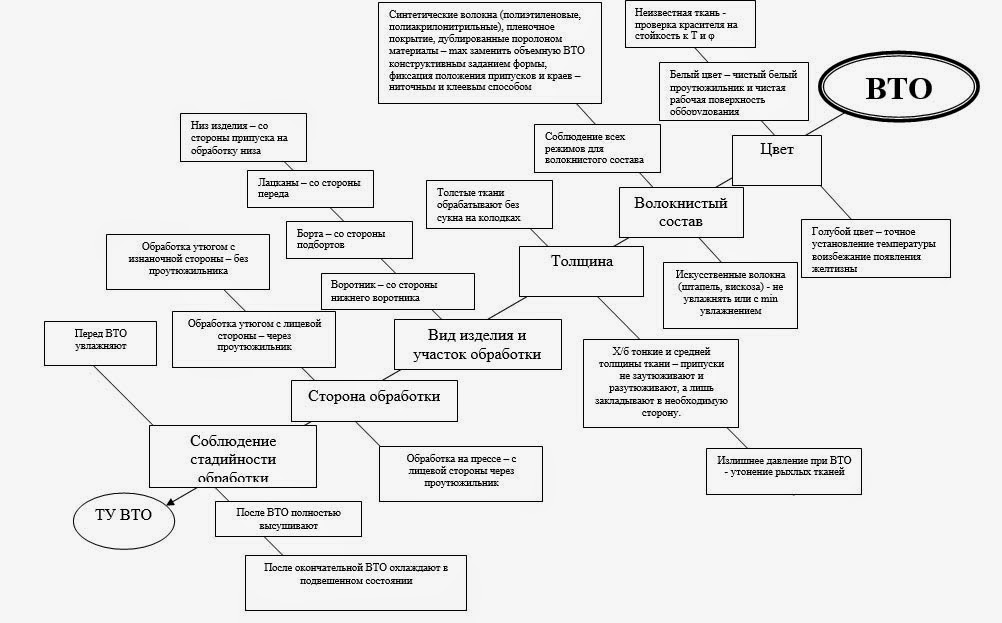

When performing the WTO, as with other types of treatment, it is necessary to observe the technical terms and rules that allow to achieve a good result at minimum cost and to avoid processing defects. Details of the technical conditions prescribed for each operation of the WTO taking into account the specifics of the operation (phases of treatment, type of treatment, used equipment and adaptations, qualifications, properties of the fabric/package, etc.), but there are General guidelines do not prescribe in the formation THAT operations relating to the WTO:

Compliance with the stage of processing (hydration before the WTO, after full drying of the WTO, and drying the final WTO for 1-1. 5 hours in limbo or on a mannequin) and allows better handling and a more stable in the process of operation form of the product.

At processing methods of Ironing and pressing, i.e., iron and the press, should observe the following principles:

- Treatment on iron on the reverse side of the surface, or seams/sections is done without proteinlike, from the front — always through protohellenic.

- Treatment on the press surfaces are made only from the front side through protohellenic.

- WTO products and parts on line is always on the side which is not visible in the product worn by a person, that is, the allowance for processing of iron bottom from the seam allowance or inside, lapels priorivet from the front side from podborov collar with the bottom collar.

When considering properties of materials subjected to WTO take into account:

Products of thin and medium thickness cotton fabrics hosted the WTO are not subjected and during the machining just lay allowances of seams in the required direction. Further fixation of the allowance is made upon final WTO.

3) fabric colour — if you use undiscovered krasitelei you should explore the durability of dye to the effects of temperature and moisture. Special attention should be remove tissues of white color and blue color, as the first easily get dirty, and blue dyes have a low resistance.