Description connecting joints will be made in the manner specified by the classification in the following form: the name of the scheme or section, example applications, a description of the execution process and the possible technical conditions (TU). Well there you go...

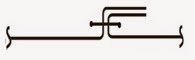

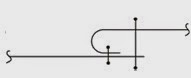

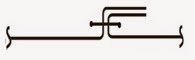

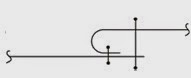

Connective bridging vrazalic

Applications: connection parts of the top in the products thick and medium thickness of the fabric - shoulder, side seams, front and elbow seams and sleeves.

Description of the process execution possible:

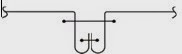

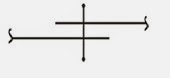

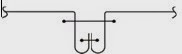

Details folded face inward, rough-cut slices. Details grind off sh.sh. 5-15 mm. Details unfold in opposite directions relative to the connection lines, the allowances are laid out in opposite directions and are fixed by the wet-heat treatment) of the WTO. Connective bridging usautoco

Applications: the connection of the parts lining, detail at the top in products from fine fabrics and linen products.

Description of the process execution possible:

Details folded face inward, equalize the slices. Details grind off sh.sh. 5-15 mm. Details unfold in opposite directions relative to the connection lines, the allowances are placed in one direction and fixed by the WTO.

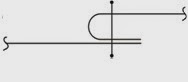

Connective bridging on an edge

Area of application: connecting wedges skirts.

Description of the process execution possible:

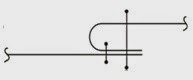

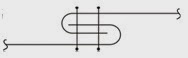

Details folded face inward, equalize the slices. Details grind off sh.sh. 5-10 mm. Details unfold in opposite directions relative to the interconnect lines. Connective bridging topstitched

Applications: connection parts of the top in the products from natural and artificial leather, suede, products sports style

Description of the process execution possible:

Details folded face inward, equalize the slices. Details grind off sh.sh. 5-15 mm. Details unfold in opposite directions relative to the connection lines, the allowances are placed in different directions and are fixed by means of finishing lines at equal distance from the line of stitching ( W.sh. 1-10 mm). Connective invoice with an open cut

Applications: connection parts gasket, nastraivanie braid, stitch the bottom of the collar to the neck of the product (zigzag stitch)

Description of the process execution possible:

Details superimposed on each other inside out on the front side with a length of 8-12 mm and lay a line of sh.sh. 4-6 mm

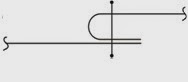

Connective invoice with a shut cut

Scope: attaching the yoke, nastrojkah straps, patch pockets, stitch the bottom of the collar to the neckline of the product

Description of the process execution possible:

The edge of the top part inside out iron on 5-12 mm On the front side of the bottom part plan a line of orientation of the bend of the top part. The upper part is applied to the front side of the lower bend to the intended line (rarely with a combination of slices) and scribbled sh.sh. 1-5 mm

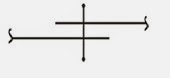

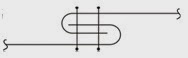

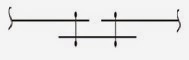

Connecting nastroni open cut

Applications: the connection of the side, the shoulder sections, the middle sections of the backrest in the presence of finishing lines, including leather, suede, mantle materials.

Description of the process execution possible:

Fold the details right sides inward, overlapping the slices, and grind off sh.sh. 7-15 mm Details unfold in opposite directions relative to the connection lines, the allowances lay to one side and scribbled (often from the front side) sh.sh. 1-10 mm

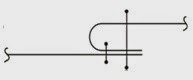

Connecting nastroni with a shut cut

Area of application: connecting of slices in the presence of finishing lines, including leather, suede, mantle tissues for bulkier seam.

Description of the process execution possible:

Fold the details right sides inward, with the release of lower parts for the upper 5-7 mm, and grind off sh.sh. 5-10 mm Details unfold in opposite directions relative to the connection lines, the allowances are laid to one side and scribbled (front side) sh.sh. 6-11 mm In this place the attentive reader will stumble on information about the connecting linen lapped seam. In the classification scheme he seems to be one, actually two of them: connecting linen narrow lapped and lapped linen connective broad. When I'm not lazy, I pattern classification correct;) But the information in this report will have two seams.

Connecting linen narrow lapped

Field of application: grouting the bedding and underwear, working clothes

Description of the process execution possible:

Fold the details right sides inward, with the release of lower parts for the upper 7-8 mm. Lower part bordered by an upper cut and at a distance of 1 mm from the edge of the bottom part is laid place. Details are arranged in opposite directions relative to the interconnect lines. "Packaged" allowances details turns with respect to the line towards the upper parts and nastraivatsa at a distance of 1 mm from the bend. Connective lingerie lapped wide

Field of application: grouting the bedding and underwear, working clothes

Description of the process execution possible:

Fold the details right sides inward, with the release of lower parts for the upper 8 mm. Details grind off sh.sh. 8-9 mm Allowance of the bottom part round the cut of the top part, then bend the seam allowance to the side of the top part relative to the connection lines, and the details unfold in opposite directions. Allowances scribbled on the top item sh.sh. 1 mm.

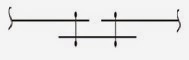

Connective lingerie double

Field of application: grouting the bedding and underwear, working clothes

Description of the process execution possible:

Details folded wrong side inside, cuts call. Details grind off sh.sh. 3-4 mm. The corrected seam wrong side out, straightens on the edge. On the reverse side is laid a line of sh.sh. 5-6 mm

Coupling the linen in the castle

Field of application: grouting the bedding and underwear, working clothes

Description of the process execution possible:

The seam allowance of 6-8 mm on the top part and iron on the wrong side, the lower part on the front side Details fold, okantovany allowances of one part cut the other. Lay two lines of the sh.ø 1 mm from the bend.

Connecting seam butt

Application area: connecting parts gaskets. Unconventional connection of details of clothes with elements.

Description of the process execution possible:

Details applied to a strip x/cotton fabric (substrate) for 10-20 mm backing down to butt each other (or with a fixed distance between the slices) and scribbled sh.sh.5-10 mm