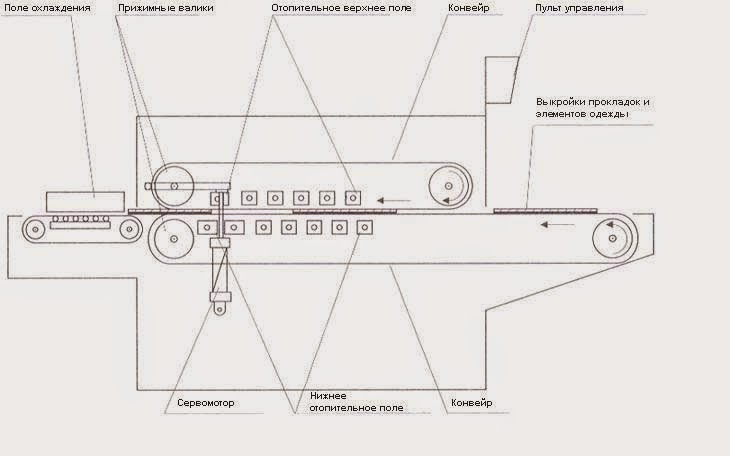

The bonding process may be performed on garment presses.

Their design allows you to adjust the temperature, pressure and time parameters that significantly affect the quality of the connections.

The main parameter is temperature, which must be adhesive to its tack was the highest, that is, the temperature in the gap between the gasket and the top fabric (it can be measured by using thermal paper). Heat to penetrate to the glue, must overcome the thermal resistance of the Teflon gaskets and the upper fabric with the lower heating plate. Therefore, the installation temperature of the press depends on its design and should be a few degrees above the required temperature in the gap. The duplication time is the time from the closing plate of the press to its opening, or, in the case of the press the continuous operation, the time from the moment of entrance in the field of heating to exit. It lasts a few seconds during which the heat from the heated plates must penetrate to the glue and heat it to a temperature which yields the maximum strength of the connection. Too short time may be the reason that glue will not have time to obtain the desired temperature and will be too hard. Too long time will result in overheating of the glue and eventually it will melt. It will be absorbed in the lining and the fabric, causing them stiffness, but the connection is weak. Pressure (pressure, pressing force) is a parameter that determines the pressure exercised by the upper plate per unit surface. Too weak to entail podavlenie glue across the strip from the top fabric. Too large will entail podavlenie glue across the strip (pass glue), or excessive flattening of the adhesive dots, and the result is a solid sticking connection. It is important that the pressure was uniform.

When using the iron rules of the gluing adhesive strips to the following: -Heat iron to the temperature recommended by the manufacturers of the gaskets; - the part on the table wrong side up, place the gasket on the required sections of the adhesive surface down. Working with great detail, start duplication from the middle of the part moving to the edges. Rearranging the iron, keep melting region overlaps each other. First, you need priotity lightly, then priotity again;

- Hold the iron on each section for 10-15 seconds;

- Let the parts cool down, as the warm strip is easily deformed.

On the cold parts check the quality of bonding pads.