· Semilla (figure 1) is used to separate the bark from the rod. Metal semelka (a, b) long, 35-40 cm with a round or oval hole and the stop at the bottom made of steel wire with a diameter of 10-15 mm. the Simplest wooden semelka can be cut from a willow stick with a thickness of 2-4 cm and a length of 40 cm from one end of its focus to insert into the ground if the sanding is done right on the spot, billet, or if you work at home, semelka fix in a workbench (d), the Board, the balance beam. The other end memilki breaks down to half, and the crack put the rod and stretch it – the bark is removed.

Figure 1

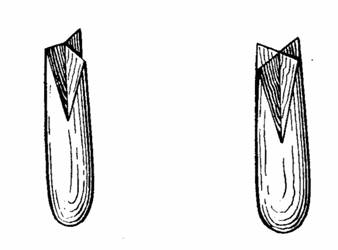

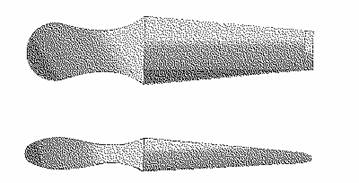

· Kolonki (figure 2). Used for splitting rods of willows into 3 or 4 parts, called tires. Kolonki made from solid wood with a length of 6-8 cm, with a diameter of 3 see the Back end kolenkow convex, and the other has 3-4 equal cut of the cutter.

Figure 2

· Shop (planing tool) (figure 3) – used to obtain sliced strips. Shop fixed very firmly on the table. A tire lay in the groove with the shiny side down and, holding her to him, cut the core. The result is a smoothly planed plane satin ribbon.

Figure 3

· Smol (figure 4) – tool for planing willow strips across the width.

Figure 4

· Jamki (figure 5) of steel plates are used for straightening and bending of the rods. At one end of jamki make a ring with a cutout. In the cut lay the rod that you want to straighten or bend. A rectangular groove on the other end is used for bending rods at an angle. The ring and the groove jamki should correspond to the thickness of the rods. The size of amok: length of 25-40 cm, hole diameter – 3-5 cm, width of cut of 2.5 – 5 cm.

Figure 5

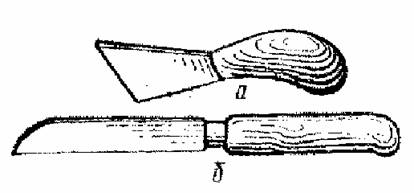

· Knives (figure 6). Gorbach (a) provides for neat trimming of the ends of the rods in wicker products. Pancake knife (b) has a universal destination. They cut off the ends of sticks and twigs, cut knots, planed and also used for cutting rod on the plantation, etc.

Figure 6

· Pruner. Ordinary garden secateurs, the main and sometimes the only tool in the harvesting of cane. It is also widely used in weaving for trimming the ends of the bars, etc. works.

· The hammers. Hammers should be two. With a mass of about 0.5 kg and 150-200 g.

· A pair of pliers. They are used when you need to pull a bent nail, to cut the wire used for some designs of handles, pull broken and already braided rod, and other works.

· The pliers. They are used to bend the rod at right or acute angles without fracture.

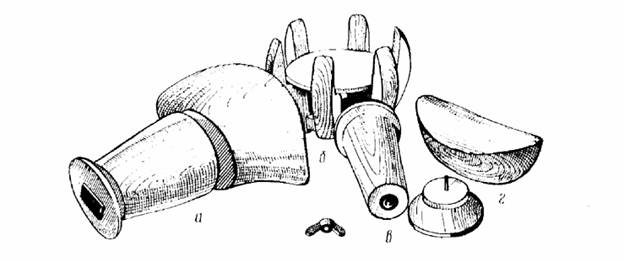

· 'isère (figure 7). This tool is only for weaving. Make it metal or wooden. With the help of Ysera compacted the weave of the walls of large items. Metal isère pounding like a hammer (flat part), upsetting the weave. Wooden is applied to the top row of the netting and hit the isère with a hammer. Pointy, almost like a screwdriver, the end of Ysera allows you to push the dense rows of weaving. It can also be used as a powerful lever or a wedge, if required. Wooden'isere is made from solid svilevatoj (napravlennyh) wood to last longer and not split from the blows. All edges Ysera scroogled that they are not damaged by rod when striking.

Figure 7

· Clips. As clips can be used plastic clothespins. they can be no increase in the number of fingers on your hand.

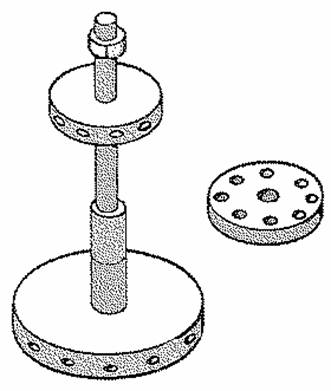

· Templates – use for the manufacture of very many products, especially mass production. There are different types of templates: hoops and frames (referred to as bugulama) different shapes and sizes, the pattern Board and pattern-pattern (figure 8), the generic template (figure 9).

Figure 8

Figure 9

· Awls. There should be several different sizes and shapes. Widely used diamond awl. It is constantly at work, especially when braiding the bottom and the handles of the baskets. This pain can be easily powertel holes in the rod, or stick, not shattering it. It is not necessary to sharpen the end of sewing is better when the end is slightly blunted.

In addition to these tools and devices you will need another Desk, comfortable height, preferably with drawers for tools and a low chair. In addition, the required drill with set of drill bits (for drilling holes in the templates, in the places where you will have to go withe, etc.), wire cutters, saws (for wood), screwdrivers, screws, small nails, thin and soft wire, a trough or tank to soak rods and other tools and devices that are in the process, the wizard invents and manufactures.