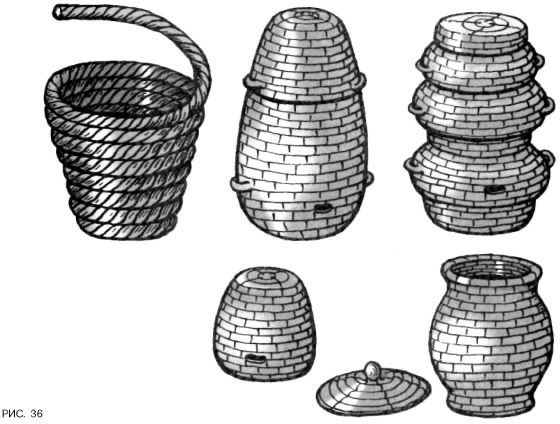

In the Caucasus, in southern Russia, this way the clay beehive, the so-called sepedi. Such hives were also common in Greece, Iran and Afghanistan. But since the hive often had to carry, to lift high into the mountains to Alpine meadows, clay sepedi was not very comfortable — they were heavy and easily broken. So soon instead of clay for the manufacture of harness sapatos began to use a straw. The hive, woven straw bundles, was not only lightweight and unbreakable, but due to the low thermal conductivity of straw is not overheated inside from the scorching rays of the sun and not overcooled in the case of lowering the air temperature (figure 36). Straw walls protect the bees from rain and chilly winds. More complex hive-tapetki consisted of several parts-the extensions, which houses reserves of honey and broodnest of the nest. Such capecci had a complex shape and different sculptural expressiveness.

From straw plaits peasants weaving all kinds of baskets, pots, boxes intended for storage of various products.

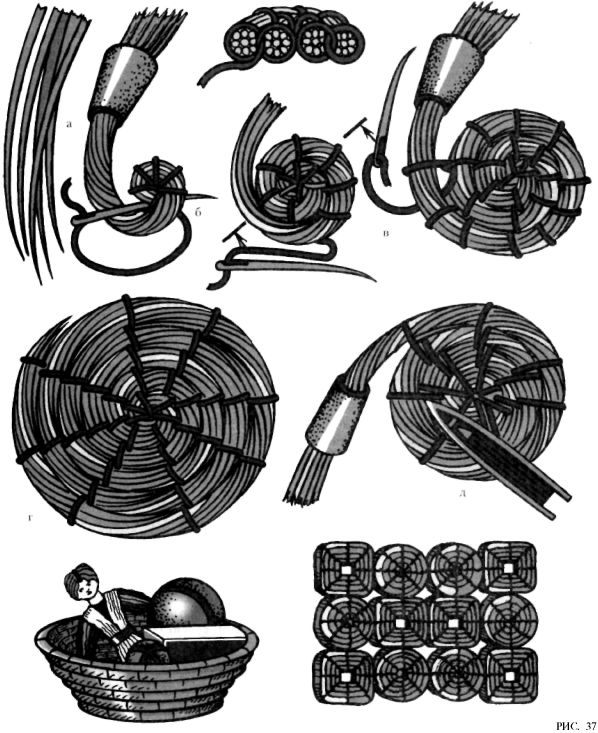

The essence of this type of spiral weave is that slightly twisted straw harness is wrapped with a strong cord and laid in a spiral tight turns.

Spiral technique of weaving gives the ability to produce a variety of products that can be used in both rural and urban life, — mats, various baskets, bowls and dishes for vegetables. In Western Europe it is very common large wide basket of straw delahanty children's toys. Unlike, say, from plastic, this basket is safer because it has no sharp corners, no cracks, forming sharp chips, and therefore can not injure a child. Besides the attractive and modern city apartment is the beauty of handmade products and natural materials.

For weaving you can use almost any herbaceous materials, such as reeds, rushes, cattail, straw rye, wheat, oats, rice and wild grasses. And for the cabling harness is not required to be of selected material which is required for other types of weaving. Therefore, most masters allowed to spiral products waste plant materials.

In a twisted and laid in a spiral harness disguise all sorts of imperfections of the material. Wind and fasten the harness with a piece of string from plant materials — flax or hemp fibers.

Before weaving the grass be sure to moisturize. The most difficult is the beginning of weaving, when it is necessary to form the first two turns, but then the process of weaving comes almost automatically. Start weaving with some subtle stems, stacked together, wrapped with twine and a roll in the small ring (figure 37 a). Ring is wrapped several times with string, gradually twisted around it the remaining part of the harness. After each revolution the needle every time you slip under the next round of twine, located on the previous spiral (figure 37 b). With increasing diameter vypechennogo circle distance between the turns of twine will be increasing all the time. To prevent this, it is necessary from time to time to make idle twine around the harness. Only after that you can pick up a NEEDLE another round of twine.

To put coil harness was sturdy enough, it should twist in one direction.

In addition, be sure that its thickness is always constant, in time adding new tufts of grass. To control the thickness of the wires you can use a metal or plastic tube. Some of the weavers used for these purposes the sleeve razlichnyie, which saw off the bottom (figure 37).

Stacking a rope with a spiral in one plane, get circles of different diameter, which can be used as coasters for hot pots or as a mats. If you need to weave dish, bowl or deep basket, in the process of weaving every next round harness increase or decrease depending on the shape. Wanting to make the walls of the cylindrical vessel, bundles of the same size build up vertically. When you increase the diameter of each next round the vessel extends, and at lower narrows.

In the manufacture of large items, the string may occur several times to build up: to the old tie a new one, but in such a way that the node could be hiding between the strands.

If the harness is shrink wrapped and not very thick twine, and coarse thread, instead of a needle it is more convenient to use a special wooden Shuttle (figure 37 d). It is cut from birch solid wood, pear, Apple or beech. The Shuttle is wound quite a large stock of twine or thread, and it allows you to braid straw harness almost continuously.

Finishing work on each item, the rest of the harness trimmed or cut so that it smoothly passed in a thin tip (figure 37g). Only after that he wrapped with twine. Thanks to this reception the connection point of the harness is not very noticeable.

Having mastered the techniques of coiled weaving of plaits, you can successfully use this technique in the creation of new, maybe not very traditional products.