Main ingredients:

• 400 g of silicone bases

• 16 g of hardener

• 140g transparent soap base

• 1/4 spoon pearl

• 3 drops of red,

1 drop green liquid dye

• 5 drops essential oil of ginger

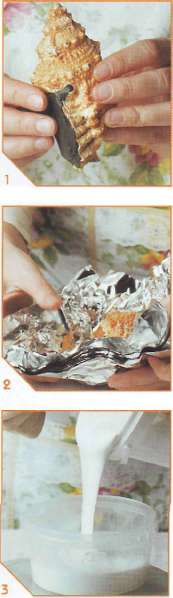

1. To sink surfaced in the silicone solution, the hole will close up the clay. Another option is to glue it with double sided sticky tape or glue on the bottom of the tank, which will be poured the solution.

2. If you cannot find a suitable container - a box of sour cream turned out to be small, and the plastic bucket is too large, and a large part of the solution is lost, use regular foil for baking, folded it in several layers. Wrap the shell with foil, and having thus, some semblance of capacity. Keep the foil tightly against the sink - between them there should be a distance of 1-1.5 cm

3. Mix in plastic container silicone compound. The ratio of base and curing agent in this case 100 g : 4 g. First weigh 400 grams basis - for the form that will be quite enough.

4. Add in a container of Foundation 16 g of hardener. Stir the solution thoroughly, otherwise the reaction will take place not throughout the mass, and the solution hardens.

5. Pour the solution into a container made of foil. If a solution is not enough, mix another batch and pour on top.

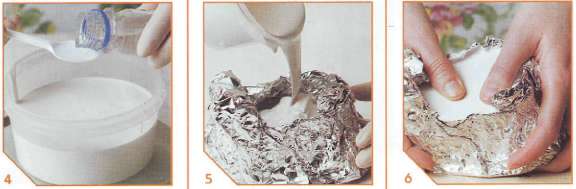

6. After 8-10 hours, the silicone will harden. If some areas are still soft, put the work away for a few days.

7. Scissors, cut the foil at the bottom of the form. If silicone spills under the sink, remove the excess with a knife, scissors or blade to Remove the sink.

8. Carefully trim the edges of the form. Odor out of the silicone mold in a few days.

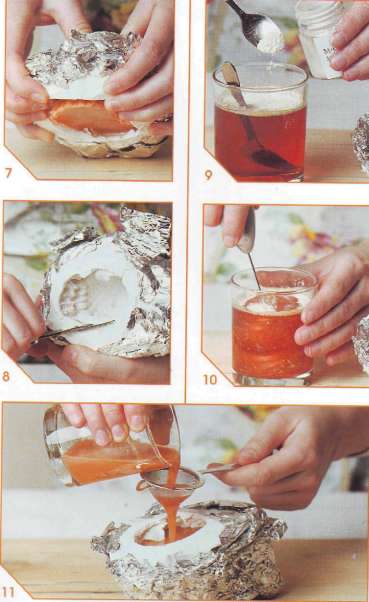

9. Melt the transparent soap BASE. To the future soap was most similar to the shell, add a base of liquid colorants, pearl and the essential oil of ginger.

10. To get rid of lumps, mix thoroughly the mixture a mini-blender.

11. Pour it into the silicone molds through a small strainer to hold the remaining globs of nacre. After 30 minutes the soap is ready. It is extracted from the flexible mold easily and without damage.

Remember, silicone molds are quite durable, but work with it gently, not putting any extra effort, without making any sudden movements.

The Council

Keep silicone molds of their own making, they are still useful for work.